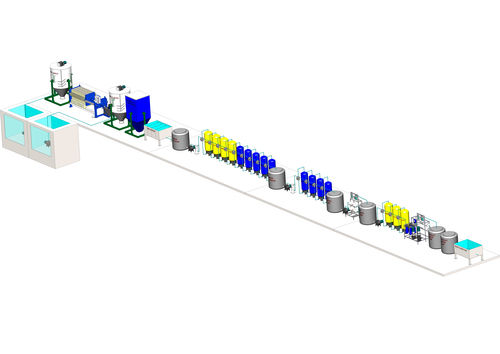

Zero Liquid Discharge System

Product Details:

- Recycle Rate Up to 95%

- Water Out Conductivity < 10 S/cm

- Ph Level 6.58.5

- Efficiency (%) Up to 99%

- Noise Level < 70 dB

- Power Consumption Based on plant size, typically 20100 kW

- Flow Rate 10100 m/hr

- Click to View more

Zero Liquid Discharge System Price And Quantity

- 3000000.00 - 15000000.00 INR/Unit

- 1 , , Unit

Zero Liquid Discharge System Product Specifications

- < 10 S/cm

- Zero Liquid Discharge System

- Up to 95%

- Up to 99%

- 415 V

- < 70 dB

- Based on plant size, typically 20100 kW

- 6.58.5

- 5000500,000 liters per day

- Up to 99%

- Containerized or Skid-mounted

- Centrifugal, High-pressure

- Direct coupled pump

- 10100 m/hr

- Electric

- High recycling efficiency, lower sludge generation

- 50 Hz

- Fully Automatic

- Stainless Steel, FRP

- Chemical, textile, process industries

- Customizable as per requirement

- Industrial wastewater

- RO, MEE, ATFD, UF, NF

- Pre, micro, ultra, nano filters

Zero Liquid Discharge System Trade Information

- 20 , , Unit Per Week

- 10 Days

Product Description

Zero Liquid Discharge System is required for treatment of wastewater produced by various industries. It has been provided with brine concentrators for re-processing of rejected RO stream. This system is highly appreciated for assuring no liquid discharge throughout its processing. It is also known to have clarifiers, filter press, evaporator, crystallizer, and RO system. This treatment plant is highly appreciated for having ability to recover up to 95% of feed water for reuse. At the end of processing, Zero Liquid Discharge System produces solid cake of contaminants for ensuring safe disposal. It is also known to have ability to remove heavy metals by flocculation & coagulation.

Technical Specification

|

Dimension |

1.6m x 0.95m x 1.5m (LxWxH) |

|

Power |

55 kW (W) |

|

Voltage |

380 V |

|

Country of Origin |

Made in India |

|

Water Source |

Industrial Effluent |

|

Application Industry |

Manufacturing Industries |

|

Capacity (KLD) |

100 KLD |

|

Control Module |

Available |

|

I Deal In |

New Only |

|

Inlet Flow Rate(m3/day) |

100 m3/day |

|

Installation Type |

Prefabricated |

|

Material Of Construction |

Carbon Steel |

|

Treatment Stages |

Secondary Treatment,Primary Treatment,Preliminary Treatment |

|

Treatment Technology |

Mixed Bed Bio Reactor(MBBR) |

Product Details

|

Flow Rate |

150m3/H |

|

Usage |

Industrial |

|

Size |

1630x273x530 mm |

Superior Water Recovery and Compliance

The ZLD system provides exceptional water recycling efficiency, enabling industries to reclaim up to 95% of their wastewater. Its advanced treatment processes ensure discharged water meets CPCB and local regulatory requirements. Whether your operation requires a compact, skid-mounted, or containerized footprint, the system assures compliance and adaptability to diverse industrial applications.

Advanced Automation and Monitoring

PLC-based automation, combined with real-time sensors for pH, conductivity, and flow, ensures optimum performance and safety. The systems fully automatic grade and remote monitoring capabilities simplify operation and maintenance, providing reliable, hands-free management that supports both onsite and remote service needs.

Robust Design and Operational Flexibility

Built with high-grade stainless steel and FRP materials, the ZLD system offers excellent corrosion resistance, durability, and customization based on water volumes from 5,000 to 500,000 liters per day. Integrated cleaning (CIP), cooling for evaporators, and direct-coupled centrifugal pumps guarantee efficiency and long-term reliability, even in demanding environments.

FAQs of Zero Liquid Discharge System:

Q: How does the Zero Liquid Discharge System achieve high recycling efficiency in industrial wastewater treatment?

A: The ZLD System integrates multiple filtration and concentration technologies, such as reverse osmosis (RO), multiple effect evaporators (MEE), and forced circulation evaporators (ATFD), to recover up to 95% of water from industrial wastewater, ensuring minimal liquid waste discharge.Q: What pretreatment steps are necessary before operating the ZLD System?

A: Pretreatment typically involves sand filtration and activated carbon filtration to remove suspended solids, organic compounds, and other contaminants, protecting membrane integrity and optimizing downstream processes for maximum efficiency.Q: When is Salt Recovery System implemented, and is it mandatory in the ZLD setup?

A: The Salt Recovery System is optional and can be included based on specific process requirements or regulatory guidelines. It is utilized when valuable salts or zero-disposal mandates necessitate further separation and recovery from concentrated brine streams.Q: Where can the ZLD System be used, and which industries benefit the most from its application?

A: The system is versatile, suitable for chemical, textile, and various process industries where wastewater management and resource recycling are priorities. Containerized, skid-mounted, or customized installation options suit factories, plants, and export operations across India.Q: What process monitoring features are integrated for operational control and compliance?

A: The ZLD System includes real-time sensors that continuously track pH, conductivity, and flow rates throughout the process. These monitoring tools enhance operational control, ensure regulatory compliance, and allow for remote or onsite troubleshooting and optimization.Q: How does the system ensure corrosion resistance and long service life?

A: Constructed using stainless steel (SS) and fiber-reinforced plastic (FRP), the system is highly resistant to corrosion from brine, chemicals, and various industrial contaminants, ensuring durability and reliable performance over extended periods.Q: What benefits does containerized or skid-mounted installation provide for industrial users?

A: Containerized or skid-mounted configurations offer rapid deployment, ease of relocation, compact design, and minimal on-site civil works. These features reduce installation time, lower project costs, and support scalable solutions for varying production volumes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free