Commercial Sewage Treatment Plant

Product Details:

- Treatment Technique Activated Sludge Process

- Water Source Sewage/Industrial Wastewater

- Application Commercial Buildings, Malls, Hospitals, Hotels, Industries

- Ph Level 6.5 - 8.5

- Membrane Size Module based (usually 0.1-0.2 micron pore size)

- Membrane Quantity Variable as per plant design

- Installation Type Containerized Plug & Play/On-Site Installation

- Click to View more

Commercial Sewage Treatment Plant Price And Quantity

- 300000.00 - 2500000.00 INR/Unit

- 1 Unit

Commercial Sewage Treatment Plant Product Specifications

- Electric

- Up to 1000 m3/day

- Up to 3000 kg (varies by model/capacity)

- Automatic

- 15 kW

- Customized (varies by capacity and site)

- Sewage/Industrial Wastewater

- Membrane Bioreactor (MBR), Sequential Batch Reactor (SBR)

- Blue and White

- Mild Steel/FRP/Stainless Steel

- Commercial Buildings, Malls, Hospitals, Hotels, Industries

- Customizable as per requirement

- Commercial Sewage Treatment Plant

- Module based (usually 0.1-0.2 micron pore size)

- 6.5 - 8.5

- Variable as per plant design

- 50 KLD to 1000 KLD

- Activated Sludge Process

- Containerized Plug & Play/On-Site Installation

- Automatic/Semi-Automatic

- 2 - 5 Bar

Commercial Sewage Treatment Plant Trade Information

- 20 Unit Per Week

- 10 Days

- All India

Product Description

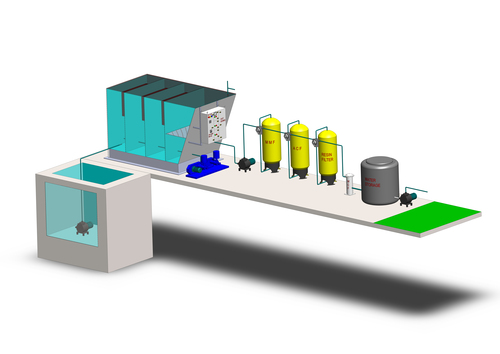

Commercial Sewage Treatment Plant is required for removing all kinds of solid & dissolved impurities from water produced by houses for assuring its reuse for appropriate purposes. It works in a series of stages which includes primary, secondary, & tertiary treatments. This plant is completely automatic in nature and operates by initially settling down solid substances by gravitational force. Then it employs use of flocculation & coagulation technologies for eliminating floating contaminants out of the system with ease & efficiency. For removal of organic matter, Commercial Sewage Treatment Plant makes use of microorganisms that eat all suspended biological substances and are later filtered away before further processing.

Technical Specification

|

Minimum Order Quantity |

1 Piece |

|

Water Source Type |

Industrial Effluent |

|

Country of Origin |

Made in India |

|

Air Blower Count |

2 Blowers |

|

Air Blower Power |

0.5 KW |

|

Automation Grade |

Semi-Automatic |

|

Control Module |

Available |

|

Deliver Type |

PAN India |

|

Feed Flow Rate(m3/day) |

101-500 m3/day |

|

I Deal In |

New Only |

|

Material Of Construction |

Mild Steel |

|

Secondary Treatment Technology |

Membrane Bioreactor(MBR) |

|

Treatment Stages |

Primary Treatment,Secondary Treatment |

|

Warranty |

1 Year |

State-of-the-Art Technology for Reliable Wastewater Treatment

Our sewage treatment plant leverages innovative MBR and SBR processes for superior contaminant removal and operational efficiency. It meets strict CPCB discharge norms, integrates vent filters and advanced odor control, and achieves outstanding water quality. The system is suitable for a wide temperature range (5C50C) and is built with high-quality mild steel, FRP, or stainless steel in a compact, customizable design.

Flexible Installation and Operation

We offer containerized plug-and-play or on-site installation models with options for skid-mounted, portable systems, ensuring minimal site disruption and quick commissioning. Automation through PLC or manual interface adapts to operational needs, while robust electrical protections guarantee safety. The plant is designed for user-friendly operation and long-term durability, with a projected service life of 1520 years.

FAQs of Commercial Sewage Treatment Plant:

Q: How does the commercial sewage treatment plant achieve high BOD removal efficiency?

A: The plant combines advanced Membrane Bioreactor (MBR) and Sequential Batch Reactor (SBR) technologies, providing up to 90% BOD removal. A multi-stage activated sludge process, combined with pre-treatment screening and grit removal, ensures efficient breakdown and filtration of organic material, achieving outlet BOD levels below 10 mg/l.Q: What are the main applications for this treatment plant?

A: Designed for commercial buildings, malls, hospitals, hotels, and industrial complexes, the plant efficiently treats sewage and industrial wastewater. Its treated water is suitable for non-potable uses such as landscaping irrigation, flushing, and various industrial processes, supporting water reuse and conservation efforts.Q: When is the treated water safe to reuse?

A: Once the treatment plant has processed wastewater and it meets the outlet quality specifications (BOD < 10 mg/l, TSS < 10 mg/l, pH 6.58.5), the treated water is safe and ready for recommended applications like landscaping, toilet flushing, or use in certain industrial operations.Q: Where can the plant be installed and how portable is it?

A: The system offers great flexibility with containerized plug-and-play, skid-mounted, portable, or traditional on-site installations. Customization allows integration into various settings, from constrained urban locations to industrial campuses, with models tailored for specific site requirements and capacities.Q: What process is involved in handling sludge?

A: Sludge generated during treatment is managed by an integrated sludge dewatering unit, which efficiently separates and compacts solids for easy disposal or further processing, minimizing manual intervention and ensuring hygienic operation.Q: How does the plant ensure low noise and odor levels?

A: With noise levels maintained below 70 dB and advanced odor control systems including vent filters, the plant operates quietly and minimizes unpleasant smells, making it suitable for installation in sensitive or high-traffic areas.Q: What are the key benefits of using this sewage treatment plant?

A: Key benefits include high purification efficiency, compliance with discharge standards, flexibility in installation, automation with safety features, reduced footprint due to compact design, cost-effective operation and maintenance, long service life, and the ability to support water reuse in commercial and industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS