Zero Liquid Dish Charge STP Plant

Product Details:

- Installation Type Prefabricated/Containerized, On-Site Installation

- Material Mild Steel, FRP Coating

- Flow Rate 50 m3/day

- Automation Grade Automatic

- Membrane Size 8 inch

- Membrane Quantity 4

- Capacity 50 KLD

- Click to View more

Zero Liquid Dish Charge STP Plant Price And Quantity

- 800000.0 INR/Unit

- 1 Unit

- 300000.00 - 2500000.00 INR/Unit

Zero Liquid Dish Charge STP Plant Product Specifications

- Advanced Membrane & Biological Treatment

- Sewage Treatment Plant (STP)

- Industrial Blue & Grey

- Sewage, Domestic Wastewater

- 2.1 m3/hr

- 3 - 4 Bar Operating

- Zero Liquid Discharge (ZLD), Membrane Bioreactor (MBR)

- Automatic

- 50 m3/day

- 5.5m x 2.8m x 2.5m (approx.)

- 6.5 - 8.5

- Mild Steel, FRP Coating

- 4

- 8 inch

- 3.5 kW

- Electric

- 50 KLD

- 1200 kg (approx.)

- Prefabricated/Containerized, On-Site Installation

- Automatic/Semi-Automatic

- Residential, Commercial, Industrial Wastewater Reuse

Zero Liquid Dish Charge STP Plant Trade Information

- 20 Unit Per Week

- 10 Days

- All India

Product Description

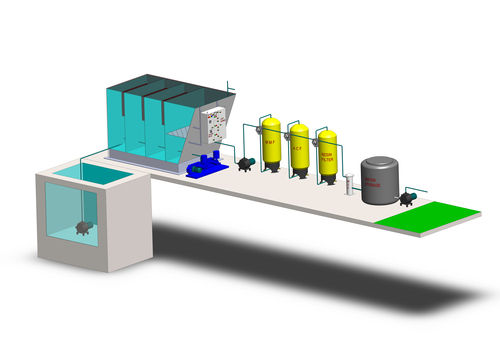

Zero Liquid Dish Charge STP Plant is required for treatment of wastewater produced by industries & houses in highly efficient manner. It is highly appreciated for producing no liquid discharge throughout its processing cycle hence completely environment friendly in nature. This plant is made having strong steel alloy made body with corrosion protective surface finish. It comprises a clarifier, chemical feeding system, filter press, ultra filtration unit, and RO system. Offered plant is also equipped with brine concentrator for further processing of rejected stream. Zero Liquid Dish Charge STP Plant is also provided with a gravity settler for sedimenting heavy impurities out from water.

Technical Specification

| Filling Principle | Atmospheric Pressure |

| Type | Vertical on ground design |

| Country of Origin | Made in India |

| Water Source | Commercial Waste Water |

| Automatic Grade | Semi-Automatic,Automatic |

| Installation Service | Yes |

| Application Industry | Textile Industries |

| Capacity (KLD/MLD) | 24 KLD - 2.4 MLD |

| Control Module | Available |

| Deliver Type | PAN India |

| Inlet Flow Rate(m3/day or m3/hr) | 2000 m3/day |

| Material Of Construction | Mild Steel |

| Treatment Technology | Mixed Bed Bio Reactor(MBBR) |

| Warranty | 1 Year |

Advanced Membrane Bioreactor Technology

This sewage treatment plant utilizes advanced MBR technology combined with Zero Liquid Discharge, delivering exceptional water quality. The system efficiently reduces Total Suspended Solids, Biological Oxygen Demand, and Chemical Oxygen Demand to surpass compliance standards, ensuring high-quality effluent output suitable for sustainable reuse.

Automated Operation and Minimal Maintenance

The plant operates with automatic or semi-automatic modes, managed by a smart PLC-based control panel. Maintenance is simplified to scheduled checks, and the automatic sludge dewatering system minimizes manual intervention. The efficient design keeps noise levels below 65 dB, making it ideal for various site environments.

Prefabricated and Versatile Installation

Built for flexibility, the prefabricated and containerized design allows straightforward on-site installation across residential, commercial, and industrial settings. The compact footprint of 5.5m x 2.8m x 2.5m ensures easy integration even where space is limited, and the durable mild steel with FRP coating ensures long-term reliability.

FAQs of Zero Liquid Dish Charge STP Plant:

Q: How does the Zero Liquid Dish Charge STP Plant treat wastewater to achieve high-quality effluent?

A: The plant incorporates advanced Membrane Bioreactor (MBR) technology alongside biological treatment to efficiently remove contaminants. With zero liquid discharge (ZLD) methodology, it ensures TSS, BOD, and COD are reduced to below 10 mg/L, 10 mg/L, and 50 mg/L respectively. Final disinfection is achieved through UV or chlorine dosing, producing safe, clear water for reuse.Q: What is the process for handling sludge in this STP plant?

A: The system features an automatic sludge dewatering unit that efficiently processes and compacts waste sludge, reducing volume and simplifying disposal. This minimizes manual handling and makes sludge management more convenient while maintaining plant hygiene and operational consistency.Q: Where can the treated water from this STP plant be reused?

A: Treated water meets strict quality standards, making it suitable for non-potable applications such as toilet flushing, gardening, and as makeup water for cooling towers. Its versatile reuse potential enhances sustainability in residential complexes, commercial facilities, and industrial sites.Q: When is maintenance required for this STP plant, and what does it involve?

A: Maintenance requirements are minimal and centered around scheduled inspections. Routine tasks include monitoring the PLC-based system, checking membrane integrity, and ensuring disinfection units are functioning properly. The automated sludge dewatering system further reduces manual upkeep.Q: What benefits does the Zero Liquid Dish Charge STP Plant offer for Indian exporters, manufacturers, and service providers?

A: It ensures compliance with CPCB/PCB norms, conserves water resources by maximizing effluent reuse, and operates with energy-efficient 3.5 kW electric systems. The automated controls, reliable construction, and streamlined installation provide long-term operational savings and regulatory peace of mind.Q: How is the plant installed and what type of wastewater can it treat?

A: The plant is delivered as a prefabricated, containerized unit and can be installed directly on-site without complex civil works. It is optimized to treat domestic sewage and wastewater with influent parameters of TSS < 300 mg/L, BOD < 250 mg/L, and COD < 500 mg/L, serving capacities up to 50 KLD.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS